The Best Strategy To Use For Freezer Freon

Wiki Article

Some Known Incorrect Statements About Cooler

Table of ContentsThe Facts About Direct Cooling Freezer RevealedTop Guidelines Of Freezer FreonFreeze Dryer Fundamentals ExplainedThe Facts About Freezer Refrigerator Inverter Uncovered

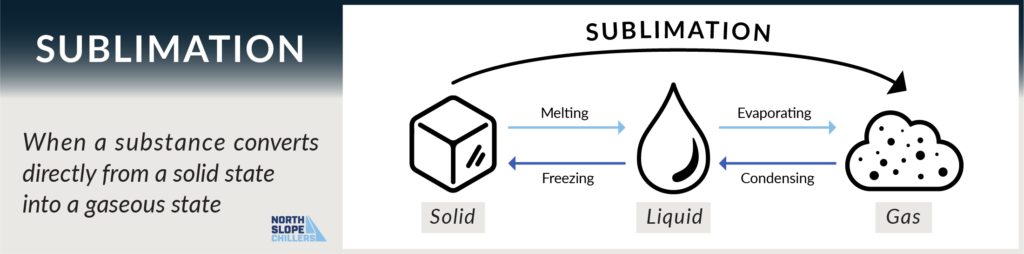

Suspended animation or lyophilization is a dehydration method based on the sublimation of water in an item (, ). This suggests that the item's water content transitions from a solid to a gaseous state or from ice to vapor without undergoing the liquid state (). Freeze-drying is considered a premium quality dehydration technique for a pair of factors, consisting of (, ): it runs at low temperature levels, which adds to protecting a product's dietary worth, preference, look, and also heat-sensitive compoundsfreezing prevents chemical as well as microbiological procedures, which significantly postpones the product's degeneration (thus expanding its service life) Raw foods are consisted of about 80%95% water, which can be separated right into "free" as well as "bound" water.In the freeze-drying process, all free water as well as some bound water must be eliminated, as well as cost-free water must stay icy in any way times. This is the primary difference in between freeze- as well as vacuum-drying and also the most tough action (). The freeze-drying process can be separated right into three steps (,, ): The item is usually iced up under atmospheric pressure.

Understood as desorption drying out, it's the drying out of products to their desired moisture by getting rid of the staying bound water - freezer temperature. Freeze-drying should be done in controlled conditions that do not thaw the water, seeing that the visibility of fluid water might change the item's composition, form, and also physical residential properties ().

Freeze drying happens in 3 phases: Freezing Key Drying (Sublimation) Secondary Drying (Adsorption) Appropriate freeze drying can lower drying out times by 30% Freezing is one of the most vital phase of freeze drying out, as well as there are numerous methods for it. Freezing can be carried out in a freezer, a cooled bathroom (shell freezer) or on a shelf in the freeze dryer (direct cooling freezer).

9 Easy Facts About Direct Cooling Freezer Explained

This protects its physical type. Freeze drying is easiest to achieve utilizing large ice crystals, which can be produced by sluggish freezing or annealing. Nevertheless, with organic products, when crystals are too large they may damage the cell walls, which brings about less-than-ideal freeze drying out results. To avoid this, the freezing is done swiftly.

Concerning 95% of the water in the material is eliminated in this phase. Main drying can be a slow process. Excessive warmth can modify the framework of the material. Freeze drying out's last stage is additional drying (adsorption), throughout which the ionically-bound water particles are gotten rid of. By increasing the temperature level more than in the primary drying out phase, the bonds are damaged in between the product as well as the water molecules.

After the freeze drying process is total, the vacuum cleaner can be braked with an inert gas before the material is sealed. Many materials can be dried out to 1-5% recurring dampness.

Freezer Things To Know Before You Buy

The fundamental concept in freeze-drying is sublimation, the change from a strong straight into a gas. Similar to evaporation, sublimation occurs when a particle gains sufficient power to break without the particles around it. Water will certainly sublime from a strong (ice) to a gas (vapor) when the molecules have enough power to damage free but the conditions aren't right for a fluid to form (freezer freon).For a material to take any kind of certain phase, the temperature level and stress need to be within a specific array. Without these problems, that stage of the material can not exist. The chart below shows the needed stress as well as temperature level worths of various phases of water. You can see from the chart that water can take a fluid type at sea level (where pressure amounts click resources to 1 atm machine) if the temperature remains in between the sea degree freezing point (32 levels Fahrenheit or 0 levels Celsius) as well as the sea degree boiling point (212 F or 100 C).

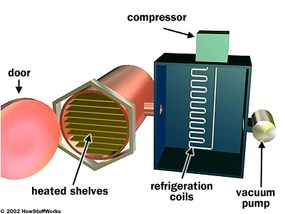

06 atmospheres (ATM), the water is cozy enough to thaw, but there isn't enough stress for browse this site a fluid to form. It becomes a gas. This is exactly what a freeze-drying equipment does. A typical machine contains a freeze-drying chamber with several shelves connected to warming units, a cold coil connected to a fridge compressor, and a vacuum cleaner pump.

When you secure the chamber and also start the procedure, the equipment runs the compressors to reduce the temperature in the chamber. The product is frozen strong, which separates the water from whatever around it, on a molecular level, despite the fact that the water is still present. Next off, the device switches on the vacuum pump to compel air out of the chamber, reducing the air pressure below.

The smart Trick of Freezer Functions That Nobody is Talking About

The heating units use a tiny amount of warmth to the racks, creating the ice to change stage. Considering that the pressure is so low, the ice transforms straight into water vapor. The water vapor drains of the freeze-drying chamber, past the freezing coil. The water vapor condenses onto the freezing coil in strong ice type, similarly water condenses as frost on a chilly day.

Yes, they are indeed amongst like this the extra pricey food conservation techniques. It's essential to recognize that freeze drying is different than dehydrating.

The other day a close friend asked me if I'm as delighted about it as I was when I first obtained it. Well, I'm also a lot more excited in fact, as well as after that conversation, I headed out as well as purchased a 2nd device! To be sincere, I had not been really excited concerning the freeze dryer at.

Report this wiki page